Recertification and installation teams from Height Safety Engineers completed compliance inspections and repair work on fall protection systems for this 14-storey city office building.

An existing client of HSE had recently purchased an office building, located in the middle of Sydney. After completing the transaction, the client engaged HSE to complete a compliance inspection of the existing fall protection system.

About the site

This office building, located in the central business district of Sydney, was first constructed in the late 1960s. Ownership of this building was transferred recently to an existing client of Height Safety Engineers.

Following the completion of the purchase, HSE was engaged to undertake a compliance and recertification inspection of the existing height safety system on the building, to determine its compliance with current Australian standards and whether or not it was fit for use.

Although these inspections are required to be undertaken on a regular basis (at least annually, under current standards), it appeared that the last inspection was completed in 2015, seven years ago.

Recertification technicians from HSE attended the site in late April 2022 to complete the inspection.

Checking the existing system

Upon attending the site, the HSE technicians discovered several issues with the installed system, many of which placed anyone using the system at significant risk of suffering a fall from height. Such a fall would also likely result in significant injury, or worse.

The initial system installation appeared to have been completed in 2008, with some upgrade work added several years later, in 2015. However, information signage, which provides system details and inspection logs, was absent in many areas of the building.

Our team determined there were several areas in which the existing system was not compliant with Australian standards. Existing fixed ladders were not compliant, and installed fall arrest anchor points had not been installed in a manner that allowed workers to use the system while remaining in fall restraint.

When considering options to rectify the system and bring it into compliance, the team raised concerns about the structural integrity of the roof itself. This was referred to a structural engineer to determine whether or not the roof would support the loads required to safely work at heights.

Ladder issues

There were three fixed ladders found during the inspection to be non-compliant.

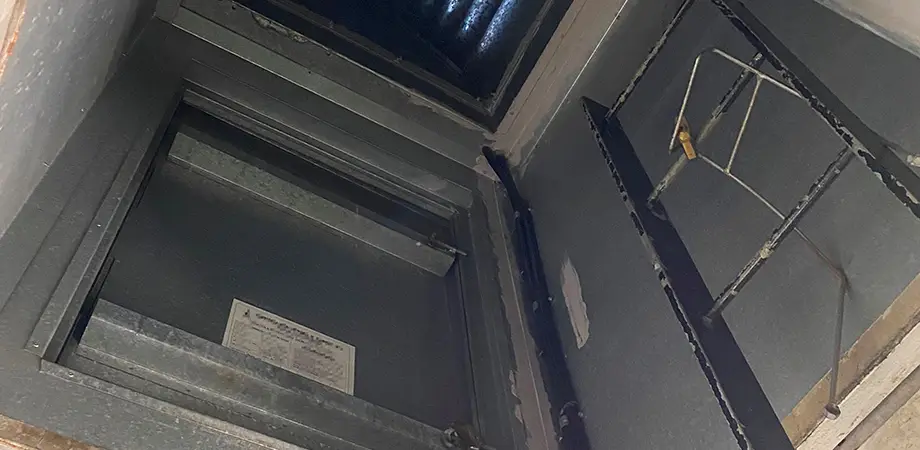

Inside the building, a ladder leading to a roof access point required a worker to use both hands to release the padlock on the door, then step sideways across the void to access the roof.

To resolve this issue the recommendation was to remove the ladder completely and permanently close off access through that door. Safer alternate access was available nearby.

On the roof, another fixed ladder was found to be non-compliant. This ladder, measuring over 7 metres in height, had fixtures that were severely rusted and not spaced properly. Ladders greater than 6 metres in height are required to have a rest platform (sometimes referred to as a change of direction platform) as part of their construction. A platform was not present. It also lacked certification signage that detailed its installation date and confirmed compliance.

The final ladder, which is used to gain access to a plant area on the roof, had a top rung that was not above the level of the landing. The bottom rung also had uneven spacing to the bottom landing. It did have a certification signage; however it was incorrectly located in an area away from the ladder itself.

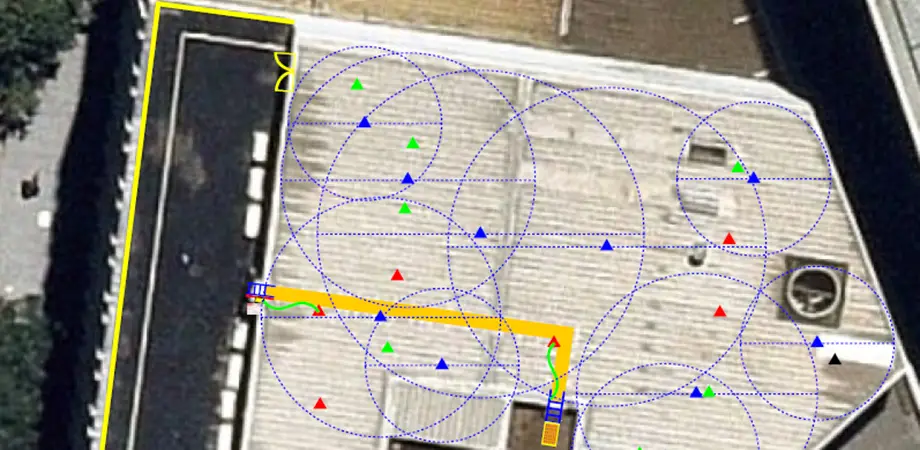

Anchor points and pendulum

Several anchor points were located around the roof, with the vast majority of them found to be out of pendulum with the roof edges. This means that workers using these anchor points are at risk of a fall off the edge of the roof.

There were also sections of the roof where it appeared the underlying structure had been compromised. To our team, it appeared as though it would be unlikely the structure would be able to support the anchor points if they became fully loaded in the event of a fall. This would mean that a worker could potentially fall the full 14-storey height of the building to the ground below.

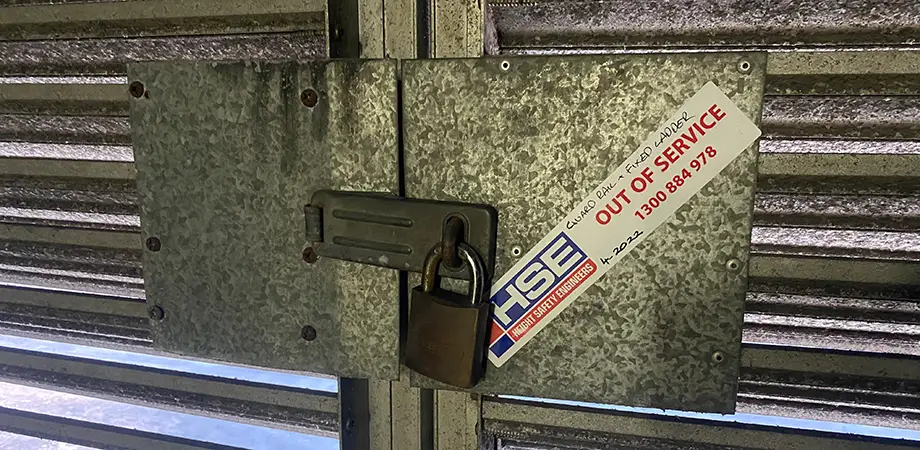

Guardrail issues

A 23-metre section of concrete-mounted guardrail was located outside of the plant room. The inspection found that in two areas the guardrail had not been installed correctly. Many fixings were not sufficiently tightened to hold the guardrail into the roof structure, and in some areas where missing altogether. This meant the guardrail would not support a horizontal load in the event of a fall, risking a worker being sent over the edge of the roof.

Rectification work

Following completion of the recertification report, HSE designers began preparing plans for rectification work required to return the system to a state of compliance and being safe to use.

First, a large section of non-compliant guardrail would be removed and replaced with 27 metres of new guardrail installed in line with manufacturer instructions and compliant with the Australian standards.

The existing 7.2 metre ladder would also be removed and replaced with a new one. The new ladder would also incorporate the required rest/change of direction platform as well as a ladder line. The ladder line is a tensioned steel cable onto which a worker connects. In the event of a fall, it prevents the worker falling to the bottom of the ladder. This minimises the risk of injury occurring.

The ladder into the plant area would be modified to make it level where required and fix the spacing. Its fixing bracket would be relocated to a compliant location and a landing platform would be installed at the base of the ladder to provide firm grounding.

Finally, it was proposed to remove seven of the existing anchor points that were out of pendulum and install 10 new FrogLink anchors from SafetyLink in a compliant layout. A small amount of guardrail around some air-conditioning ducting would also be installed.

Being able to certify these new anchors as compliant would depend on the outcome of a structural engineer’s inspection of the roof to determine its load bearing capacity. In the event the roof is unable to support the loads generated in a fall, an alternative solution would need to be found to allow safe access to this area of the building’s roof.

Project details

- Suppliers:

- Sayfa – Guardrail, ladders, rest platform, ladder line

- SafetyLink – Anchor points

- Anchor points installed

- 10x SafetyLink FrogLink

- Guardrail installed

- 32m Sayfa SENTRY guardrail

- Ladders installed

- 7.2m Sayfa KATT fixed ladder with rest platform and ladder line

- Approximate total work hours on site

- 33 hours

- Project timeline

- Recertification inspection conducted April 2022 with installation of system upgrades completed in July 2022.

To discuss your safety needs with your partners in protecting people, call HSE on 1300 884 978 or email enquiries@heightsafety.net.